The Torchmate 4000 TC is your entry into pipe and tube cutting. Designed to work as an attachment to the Torchmate 4000 series CNC plasma tables, this machine is plug and play and interfaces seamlessly with your existing machine. Many fabrication shops spend a lot of time and money reworking parts that were cut on the plasma cutting machine to remove dross or correct dimensional inaccuracies. Some of these cut quality problems are caused by mechanical and electrical problems of an old or poorly maintained cutting machine; others are related to the plasma process itself. The PlasmaCAM Instruction Manual is exceptionally clear and well-illustrated. It covers the following areas in detail: How to quickly set up the cutting table when you receive it. How to use the cutting table. How to use the software, including a tutorial with several example projects you can work through to learn the system. PlasmaCam uses the DeWalt 660 trim router, but a better router is the DeWalt 611 or the Porter Cable size equivalent. I have also had great success mounting the Bosch 2.25HP router to the Samson table, using a custom mount designed by John Derby.

Plasmacam Users Manual

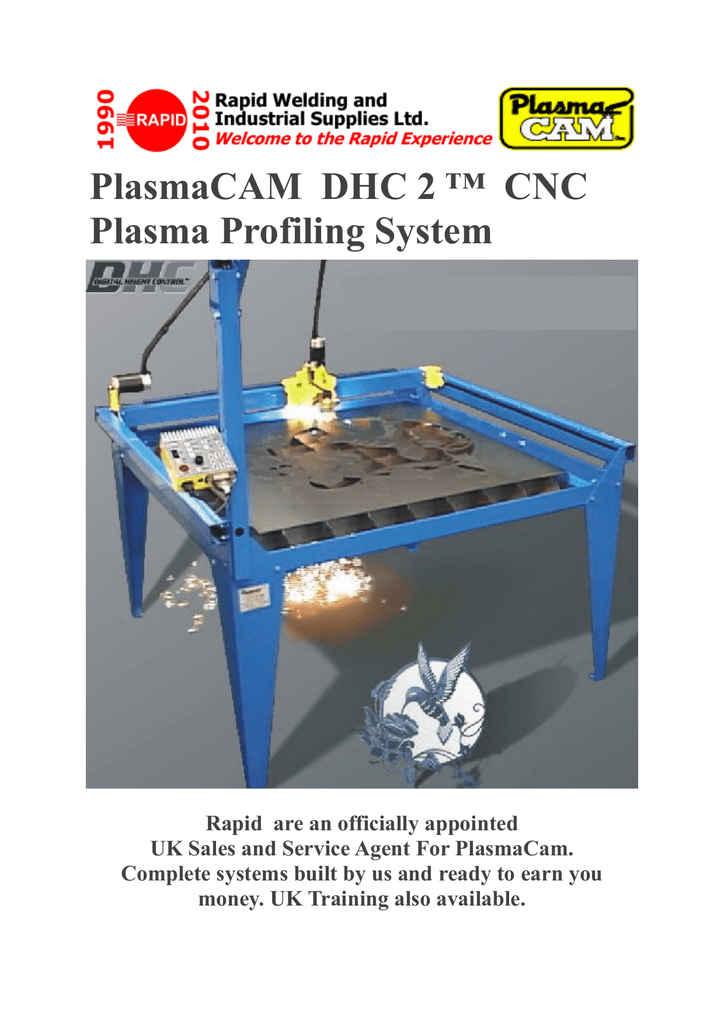

The PlasmaCam Cutting System opens up a world of opportunity to the metal artist to design and manufacture unique structures from artwork that they have created.

In addition to traditional metal signs and artwork, this cutting system allows the vintage hot rod artists to produce custom pieces for the parts that can no longer be found or manufactured.

In addition to traditional metal signs and artwork, this cutting system allows the vintage hot rod artists to produce custom pieces for the parts that can no longer be found or manufactured. PlasmaCam is located in Colorado City, Colorado and has focused all of their business attention on one CNC plasma cutting system. They have built this system from the ground up as a plasma cutting system only. Their cutting system was first engineered in 1994 and quickly became a best seller.

The PlasmaCam system comes with everything needed to begin creating custom artwork, signs, car parts, and other unique metal creations. All you need to provide is the plasma cutter and a Windows-based computer to run the design software. You will also need a hand-held torch.

The plasma cutter that you choose to go with your system, should best suit the needs of your business. This decision will be based on what size thickness that you would like to cut. Virtually all hand-held plasma torches can be mounted to the machine.

PlasmaCam recommends using a Hypertherm brand plasma cutter because of their overall performance. The Hypertherm plasma cutters are considered the most advanced system available. They are known for their precision metal cutting and reliability.

PlasmaCam sells the complete system and because there is no middleman for parts, motors, or software, they are able to sell their systems at wholesale pricing. The efficiency of their manufacturing adds cost effectiveness to the entire unit.

PlasmaCam offers a video demo packet that is beneficial in providing information about the system, a demonstration of the machine, and full specifications, along with cutter and computer recommendations. A full color brochure provides more details.

PlasmaCam Design Edge software ™ creates the designs and directly controls the machine for precision cutting. An optional product is the PlasmaCam Art Discs that contain artist created designs and patterns for use with the cutting system. The designs can be used to create any number of decorative metal work silhouettes using your plasma cutter.

The Design Edge software ™ allows you to work with your own line-art by scanning it in, or to utilize fonts on your system to create custom signs. It will convert any artwork from raster to vector and is scalable. This is the only CNC plasma cutting machine that allows you to work directly with the images that you want to cut. It controls and tracks the machine in real-time.

Plasmacam User Manual Download

The Design Edge software ™ has a simple Computer Automated Drawing (CAD) system built-in which enables precise onscreen drawing and the importing of files from other CAD software with a DXF extension. Automated functions allow for lead-ins and offset edges for accurate assembly.

PlasmaCam Cutting System adapts to other tools beside the plasma cutter, including routers, mig welders, markers, and vinyl cutters. It also has Digital Height Control ² ™, which ensures a precise distance from the cutting tip to the metal.

Plasmacam User Manual Free

PlasmaCam has an owner’s community and forum to allow for the exchange of photos and ideas, as well as collaboration on projects. Membership to the community is automatic upon registration of your system.